WELCOME TO THE NANO-WORLD. SKY IS THE LIMIT.

Fig. 1 It took over 500,000 finite elements to model this multilayer optical film with optimized Luminance Enhancement & Diffusion parameters combining BEF and Diffuser functions in one film. Surface relief is quasi-random with controlled peaks &valleys; optimized for low-cost roll to roll production. Similar films can be used in LED primary optics to improve EQE (external quantum efficiency) of single and multiple escape windows LED chips.

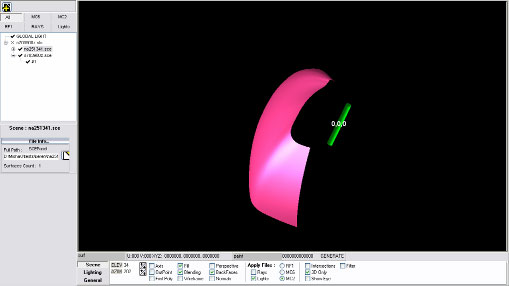

Fig. 2 Twisted and specially shaped Optical fiber.

Fig, 1 A small fragment of nonwoven fiber optical film. Be sure it is our model, not a real image under an electronic microscope. Myriads of specially twisted and shaped fibers (see figure above) fused to produce BEF & Retroreflecting & Diffusion-like films by low cost production methods. How many modeling elements? You wouldn’t believe!!!

Fig, 2 Fragment of Optical Woven Fiber

Fig, 3-7. ONLY BY KEREN™. Actual BLU luminance seen at different distances. At shorter distance there is a pronounced non-uniformity characteristic for BEF backlights. (See next three pictures)

Fig. 4 BLU luminance at intermediate distanced

Figure 5 BLU luminance at small distanced

Fig. 6 ONLY BY KEREN™. Full hemispherical luminance diagram averaged over an active area of V-groove LGP computed in a single run.

Fig. 7 Full hemispherical luminance diagram for any given domain of an active area.

Fig. 8. Directional LGP outperforming conventional LGP with two crossed BEFs by a factor 5 – 10.

Fig. 9 “DOUBLE-WINDOW” BLU for MPs with a front (shown in the picture) and main LCDs. Extractor distribution has to be modified to produce uniform luminance over both displays from a single light guide.

Fig. 10. Main LCD

Fig. 11. LGP with non-uniformly distributed simple spherical extractors. Actual extractor size: 20-50 um.

Fig. 12. Enlarged view of microextractors.

Figure 13. BEST OF ITS KIND. Asymmetric reflector for Road Lighting. KEREN is the only program analytically generating smooth reflective or refractive surface with a defined two-dimensional matrix of reflection angles . Our luminaires allow 5:1 Spacing / Height ratio and ensure highest road luminance and low glare fully compliant with CIE standards.

Figure 14. Reflector is modeled by 20,000 finite elements. Flash area at a given direction with a list of intensity values is available on-line. For a shown direction there is 190 facet producing 593cd. Notice a continuous flash area and a sharp cut-off obtainable only with special smooth surface shapes. Clearly Monte Carlo approach is the least suitable for analysis of such systems. FOVEA Engine of KEREN analyzed this reflector for 0.1 sec.